Key Takeaways

- LPNs create operational visibility. Amazon’s LPN system links every unit to its digital record, giving sellers full visibility into inventory location, condition, and movement within FBA.

- Precision drives efficiency. Each scan reduces handling errors, improves storage accuracy, and ensures faster check-ins. This precision lowers operational costs and supports consistent fulfillment speed.

- LPN data improves forecasting. Tracking how LPNs move through the network reveals SKU velocity and restock timing, helping sellers optimize buffer stock and reduce excess inventory.

- Compliance protects profitability. Proper labeling, image documentation, and record keeping ensure compliance with Amazon’s tracking rules. These steps prevent stranded inventory and support faster reimbursements.

- Strategic use unlocks scalability. Sellers who align their inbound prep, returns handling, and audits with Amazon’s LPN logic build scalable, data-led operations that grow efficiently over time.

Amazon’s fulfillment network runs efficiently, but understanding how inventory moves inside it is rarely simple. Most sellers rely on FNSKUs and shipment reports to track stock, yet these tools stop short of showing what happens once items enter the warehouse. The result is limited visibility and unpredictable inventory flow.

This is where the LPN barcode system comes in. It’s Amazon’s internal tracking framework that connects each physical unit to its digital record inside the fulfillment center. By decoding LPN logic, sellers gain insight into stock accuracy, lost-item recovery, and operational efficiency that standard reports never reveal.

In this article, we’ll explain what the Amazon LPN barcode system is, how it works within FBA inventory management, why it matters for forecasting and profitability, and how you can use it to build stronger, data-driven operations.

What Is the ‘LPN Barcode’ System at Amazon

The License Plate Number, or LPN, is an internal barcode Amazon uses to track inventory. Each code connects one physical item, tote, or pallet to Amazon’s digital warehouse record. It creates a link between where a product sits and what condition it holds.

An LPN is unique. It is generated when your shipment arrives at a fulfillment center. The code records storage, movement, and audit history. It supports forecasting and ensures accountability in every inventory flow.

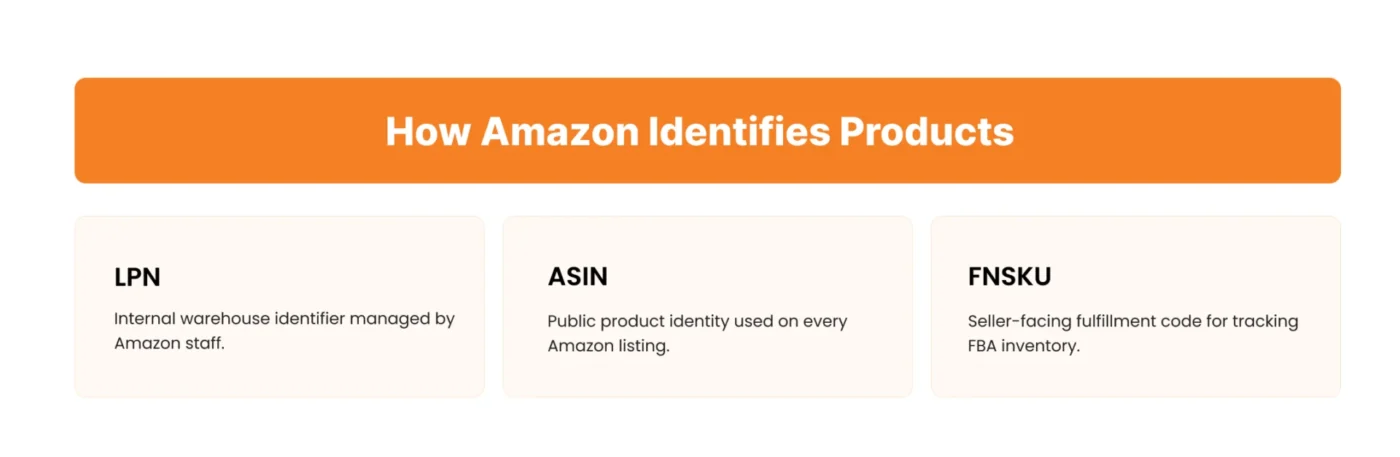

LPN vs FNSKU vs ASIN

ASIN and FNSKU are seller-visible. LPN codes are internal. They guide how Amazon tracks each physical movement.

How the LPN System Works in FBA Inventory Flow

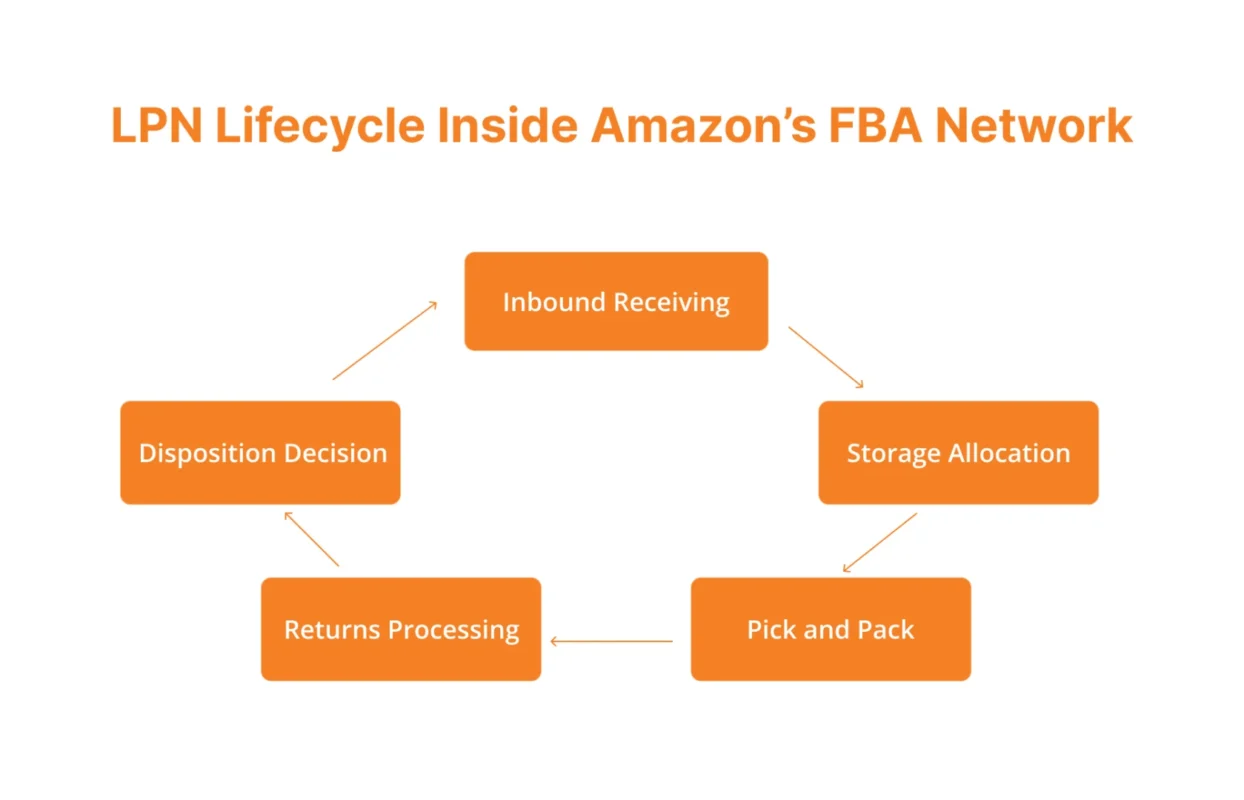

Understanding the LPN lifecycle helps sellers see how Amazon interprets every product movement. Each scan reflects a decision, a location, and a data point. Together, they form the foundation of accurate inventory flow and operational efficiency.

Inbound Receiving

When your shipment reaches the fulfillment center, each carton or tote receives an LPN barcode. The associate scans it to confirm the unit’s presence and condition. The scan activates a record inside Amazon’s warehouse management system, linking that item to your FNSKU and inbound shipment plan. This process creates accountability and ensures visibility from the first moment of entry.

Storage Allocation

After check-in, Amazon’s algorithms analyze item weight, dimensions, and demand velocity. Using this data, the system directs each LPN-tagged carton to the most efficient storage zone. Fast-moving SKUs go near forward pick stations to reduce handling time. Slower items move to deeper reserve storage. Every storage choice is driven by optimization for space, speed, and accuracy.

Pick and Pack

When an order is placed, the LPN acts as the digital address of the item. Robots or associates scan LPNs to locate the exact unit for dispatch. Each scan verifies identity, condition, and destination. This step eliminates cross-SKU mix-ups and keeps fulfillment accurate. The LPN continues to track the unit as it moves through the packing line, supporting compliance and forecasting data.

Returns Processing

Returned items often arrive with their original Amazon LPN stickers intact. These codes preserve the unit’s movement history inside the fulfillment network. Each record includes order number, storage zone, processing date, and prior condition status. By checking LPN references, sellers can trace the full life of a product, identify handling patterns, and verify whether it should be restocked, refurbished, or removed.

Disposition Decisions

Amazon reviews the complete LPN record before making a final decision. The system determines if the unit qualifies for resale, refurbishment, or disposal. That decision is recorded against the same LPN for audit and compliance tracking. This ensures that every action taken inside the fulfillment center remains visible and traceable.

Each LPN scan contributes to a continuous digital trail. That trail connects inbound accuracy, storage logic, order fulfillment, and returns reconciliation. Sellers who understand this lifecycle gain stronger control over forecasting, profitability, and operational precision.

Why the LPN Barcode Matters for Inventory Management

Once you understand how the LPN system operates, its strategic value becomes clear. Every barcode connects operational movement with financial outcomes. The system doesn’t just track inventory. It improves how efficiently your capital moves through Amazon’s network.

Turning Data into Operational Insight

Each LPN scan captures location, activity, and condition data. Sellers who interpret these signals gain insight into flow speed, restock timing, and loss recovery. The barcode acts like a real-time audit trail, revealing how well your inbound and outbound processes align with Amazon’s internal rhythm.

Building Predictable Inventory Flow

The LPN framework creates structure in a complex environment. It helps Amazon allocate, retrieve, and return items with precision. For sellers, that consistency translates into predictable inventory cycles and fewer delays in check-ins, shipments, and reimbursements. Predictability strengthens your forecasting accuracy and stabilizes lead times.

Reducing Waste and Hidden Costs

Errors in labeling, storage, or reconciliation often lead to lost stock or delayed reimbursements. LPN-driven visibility minimizes these inefficiencies. Each record validates a product’s journey, allowing you to identify where slowdowns or shrinkage occur. This control limits financial waste and improves unit economics.

Strengthening Financial and Operational Compliance

Accurate tracking isn’t just about logistics. It ensures compliance with Amazon’s performance metrics and accounting rules. Verified LPN trails help resolve discrepancies faster during audits or support cases. They protect your working capital by proving ownership and validating reimbursement claims.

Supporting Scalable Growth

Operational clarity supports growth. When your data matches Amazon’s, scaling becomes easier. You can forecast more precisely, plan inbound shipments confidently, and maintain healthier cash cycles. Brands that build LPN alignment early grow with fewer disruptions and stronger profitability over time.

The LPN system transforms warehouse data into operational strategy. It bridges movement between cost, and visibility, helping sellers manage every SKU with the precision Amazon expects.

Strategic Implications for Sellers and Brands

LPN understanding turns confusion into operational strength. Sellers who align with Amazon’s internal logic build efficiency, accuracy, and trust into their inventory systems. Each scan represents a decision point. Knowing what those signals mean helps you act faster and manage inventory with confidence.

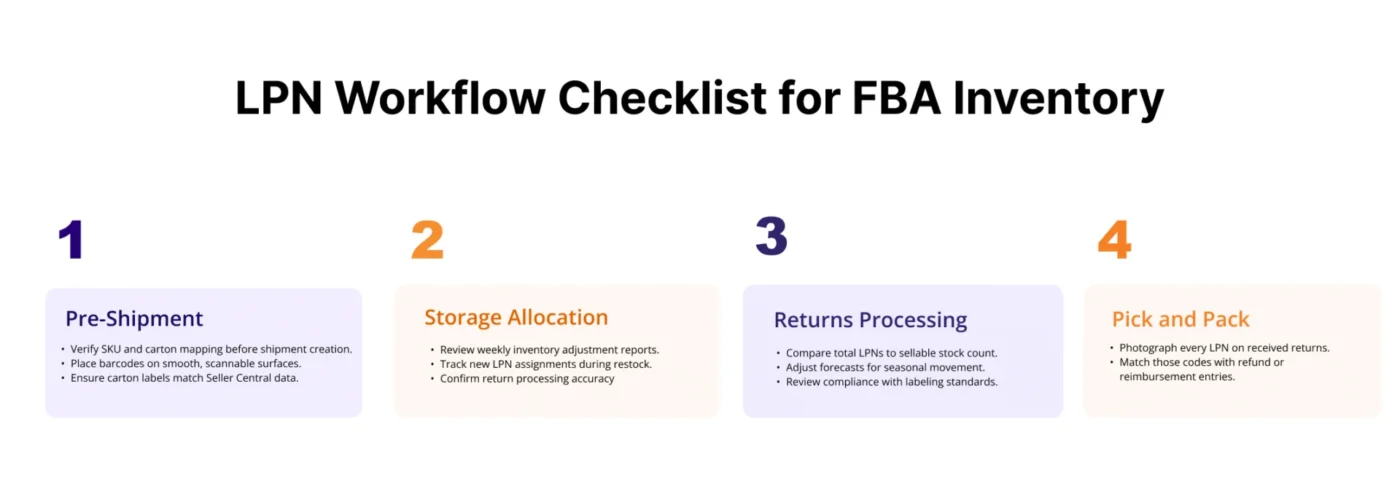

1. Proactive Inbound Audit

Prepare shipments that fit seamlessly into Amazon’s LPN workflow. Pack each carton by SKU, verify carton data in Seller Central, and use durable, scannable labels. This preparation reduces check-in delays and minimizes labeling errors during inbound processing.

2. Returns Interpretation

Treat every LPN sticker on a returned unit as a data source. Record the number before discarding packaging and use it to trace the item’s path within Amazon’s system. This process helps confirm reimbursements, identify processing errors, and maintain visibility across returned inventory.

3. Reconciliation and Reimbursement

Review your Inventory Adjustment and Event Detail reports regularly to identify uncredited LPN entries. Match those records to damaged or missing units to verify reimbursement eligibility. Consistent LPN-based reconciliation ensures accurate financial reporting and faster recovery of owed funds.

4. Forecasting with LPN Signals

Monitor how frequently LPNs relocate between storage zones to understand SKU velocity. Frequent movement indicates rising demand, while static LPNs highlight slow movers. These insights improve demand forecasting, refine reorder planning, and support balanced buffer stock levels.

5. Labeling Best Practices

Keep every LPN sticker visible, clean, and unobstructed. Avoid covering or duplicating codes, as this breaks the traceability chain inside Amazon’s fulfillment system. Proper labeling ensures smooth scanning, reduces stranded inventory, and maintains operational compliance.

Understanding these five principles transforms the LPN system from a backend process into a strategic advantage. It turns routine data into insight, helping sellers scale operations with precision, efficiency, and profitability.

| Advanced Insights and 2025 Trends LPN barcodes remain central to Amazon’s automated future. AI-Driven Optimization Fulfillment centers now use AI to read LPN scans in real time. The system adjusts pick routes and storage tiers instantly. Sellers who maintain labeling consistency experience faster receiving and lower handling costs. Predictive Inventory Flow Amazon studies LPN movement frequency to predict demand. Items that shift between zones quickly mark as fast-moving. Sellers can use this pattern to optimize reorder timing. Robotics Integration Robots rely on clear LPN visibility. A smudged or misplaced sticker slows automation. Consistent placement ensures smooth robotic scanning and compliance with safety standards. 3PL and Multi-Channel Alignment If you operate across FBA and 3PL, synchronize SKU logic with LPN mapping. Unified systems improve forecasting and maintain consistent reporting accuracy. |

Risk Management When LPNs Fail

Even the most precise systems encounter errors. The LPN framework depends on accurate scans and consistent labeling. When that process breaks, visibility drops, and inventory accuracy suffers. Duplicate codes, damaged labels, or mis-scans can create ghost inventory and delay reimbursements. For sellers, this translates into lost time, reduced efficiency, and lower profitability.

Preventive Actions

1. Review Inventory Event Detail Reports Regularly

Examine your Inventory Ledger Detail reports each month to identify inconsistencies. Early detection of missing or duplicated LPNs helps prevent data mismatches and stranded stock.

2. Keep Digital Records of Packaging and Labels

Photograph cartons, barcodes, and LPN placements before shipments leave your warehouse. These images act as verification during claim disputes or support cases.

3. Track Returned or Unsellable Items by LPN

Record each LPN linked to returned or damaged inventory. This tracking ensures that every unit remains traceable through Amazon’s system and that reimbursement claims include valid documentation.

4. Audit Stranded Inventory Before Removal

Cross-check stranded listings against their LPN references before initiating removals. This step confirms ownership, supports claim accuracy, and helps avoid unnecessary stock write-offs.

Consistent auditing builds resilience into your operations. By treating each LPN as a verifiable data point, you maintain compliance, protect working capital, and minimize operational loss.

Conclusion

Understanding Amazon’s LPN barcode system transforms inventory management from reactive to predictive. It connects visibility, precision, and efficiency into one workflow. Sellers who master this logic build reliable operations and stronger brand trust.

Your next step is simple. Review your current inbound and return processes. Compare them to this guide. Then start tracking every LPN interaction across your supply chain.

Small adjustments today create measurable gains in inventory accuracy tomorrow.

Ready to align your operations with Amazon’s fulfillment logic? Book a consultation with AMZDUDES to audit your inventory flow, optimize your inbound prep, and strengthen compliance.

Frequently Asked Questions:

1. What does LPN mean amazon?

An LPN barcode, or License Plate Number, is Amazon’s internal identifier for tracking individual items, totes, or pallets inside fulfillment centers. It links each physical unit to its digital record and supports precise inventory visibility across the FBA network.

2. Why is the LPN barcode important for FBA sellers?

The LPN system provides data transparency that standard reports cannot. It enables sellers to trace lost units, validate reimbursements, and monitor movement speed. This insight improves forecasting, compliance, and profitability within Amazon’s fulfillment workflow.

3. How to find the LPN number on Amazon?

You can find an LPN number on the physical product or packaging, usually on a white sticker applied by Amazon during inbound processing. For sellers, LPN references also appear in Inventory Adjustment or Removal Order reports, helping trace returns or reimbursements.

4. How to scan an Amazon LPN barcode?

To scan an Amazon LPN barcode, use any standard barcode scanner or mobile device with scanning capability. The code reveals internal tracking data such as item ID, fulfillment center, and condition. While sellers can’t access full internal data, LPN scans help confirm product traceability and authenticity.